AUTOMATIC LUBRICATION

We help people in manufacturing and construction with lubrication.

AUTOMATIC LUBRICATION

We help people in manufacturing and construction with lubrication.

AUTOMATIC LUBRICATION

We help people in manufacturing and construction with lubrication.

FIRE SUPPRESSION

GreasePoint, with AFEX, offers Fire Suppression Systems, providing rugged and reliable fire protection for heavy duty equipment.

PUMP REPAIR

With the help of their sister-brand, PennAir, GreasePoint offers inspection and repair services for your Graco grease and oil pumps.

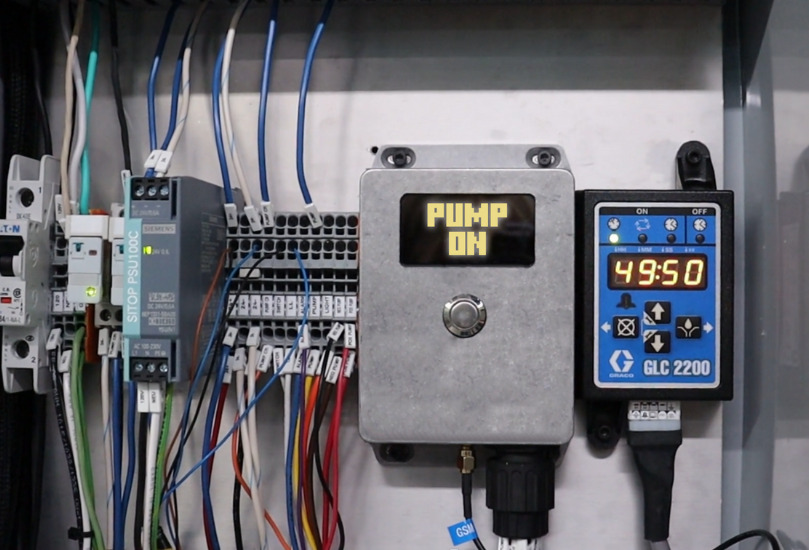

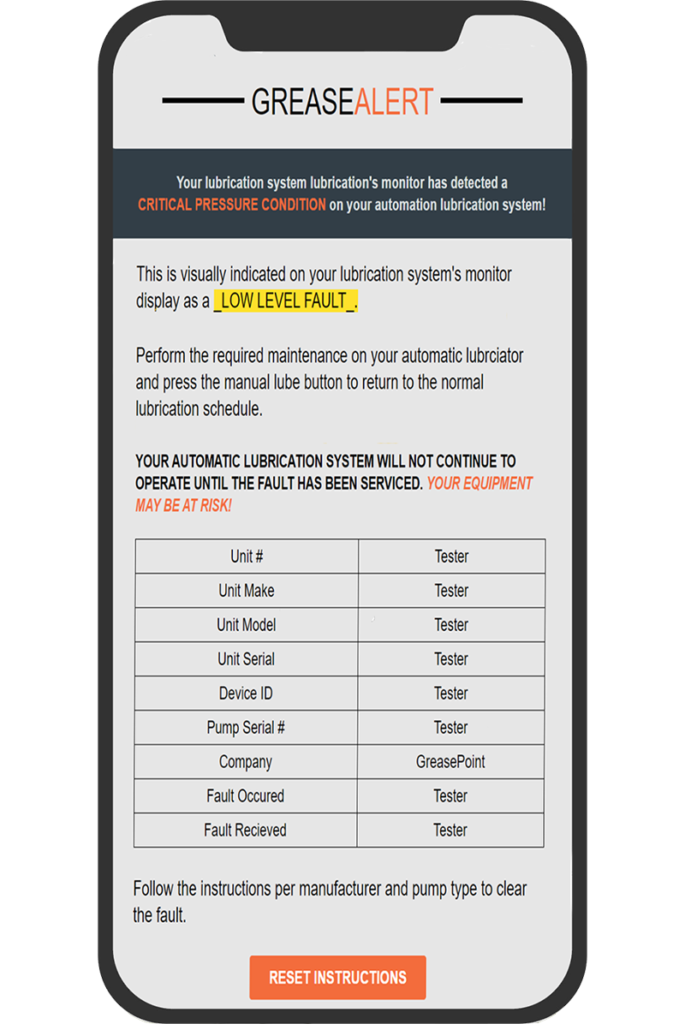

REMOTE MONITORING

With a very flexible communication platform, GreaseAlert communicates with any brand of pump or controller with data output capabilities.

HELPING, NO MATTER WHAT DRIVES YOU.

The GreasePoint team is committed to offering technical excellence, superior customer service, and world-class solutions. We work closely with specialized manufacturers providing high-quality products for on-road vehicles, off-road equipment, industrial machinery, petroleum handling equipment and other fluid handling applications.

TAKE THE GUESS WORK OUT OF LUBRICATION

Extend the life of your Heavy Duty Trucks, Trailers, Machinery, Off-Road Equipment, and Yellow Iron with Precise & Consistent Flow Lubrication.

Whether you work in maintenance, operations, or management, the pressure you experience each day is mounting. Our job is to identify the lubrication system that best fits your needs, allowing you to focus on what matters most – leaving work, at work.

- Reduce Wear and Extend Equipment Life

- Safer & Healthier Work Conditions

- Lower Maintenance Costs & Repairs

- Minimize Machine Downtown

- Improve the Environment

- Decrease Consumption of Lubrication

Let Us Lube It

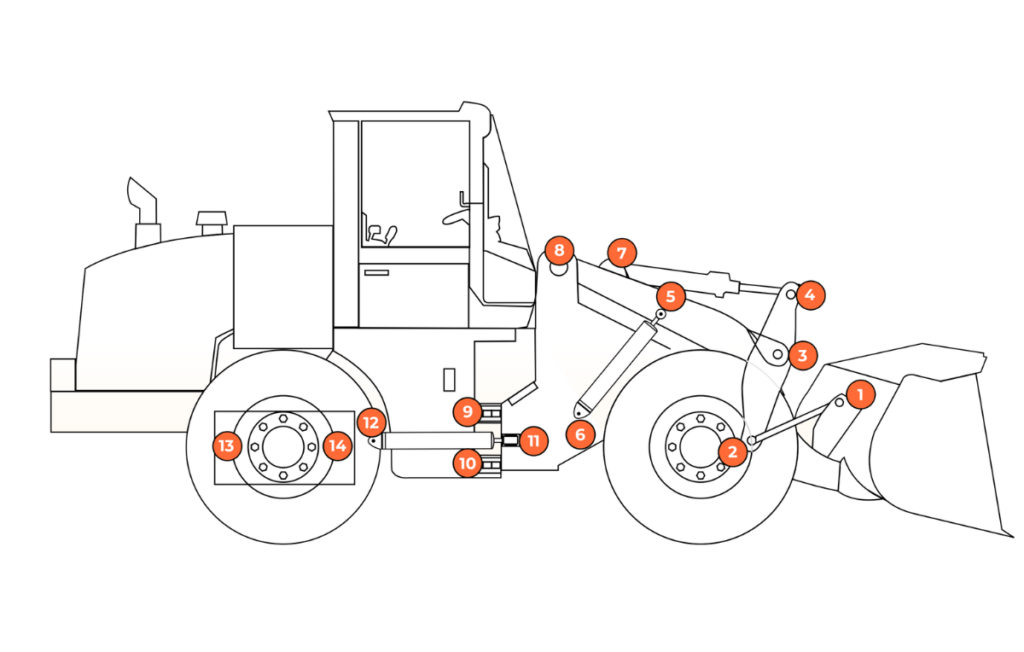

Click on the image to see all the points you can automatically lubricate on construction equipment while you work:

- 1. Upper Bucket Pins

- 2. Bucket Link

- 3. Bell Crank Pivot

- 4. Bucket Cylinder Rod End

- 5. Cylinder Rod End

- 6.Cap End

- 7. Bucket Cylinder Cap End

- 8. Boom Pivot

- 9. Upper Articulating Pivot

- 10. Lower Articulating Pivot

- 11. Steering Cylinder Rod End

- 12. Steering Cylinder Cap End

- 13. Rear Axle Cradle

- 14. Rear Axle Nose Bearing

INSPECTION SERVICES

Inspection of Automatic Lubrication systems is completed on-site by fully trained technicians. The service we provide maximizes equipment availability while minimizing unscheduled downtime and maintenance breaks.

INSPECTED

0 +

CONSTRUCTION

MANUFACTURING

FLEETS

VEHICLE SERVICES

CONSTRUCTION

CONSTRUCTION INDUSTRY

Did you know, at a minimum, heavy equipment should be greased every eight (8) hours of operation daily? However, some lubrication points have different greasing intervals. It can quickly become overwhelming.

Efficient Lubrication

Apply grease while the machine is in motion so you don’t have to stop what you’re doing or set aside time to lubricate it.

Extend Bearing & Component Life

Reduce maintenance costs and minimize downtime by extending the life of pivots, bushings, and components.

Environmental Impact

Lessen the amount of grease that comes out of the system due to over-lubrication and goes where it shouldn’t.

Safety

Reduce or eliminate climbing over and under machinery or into difficult-to-reach areas.

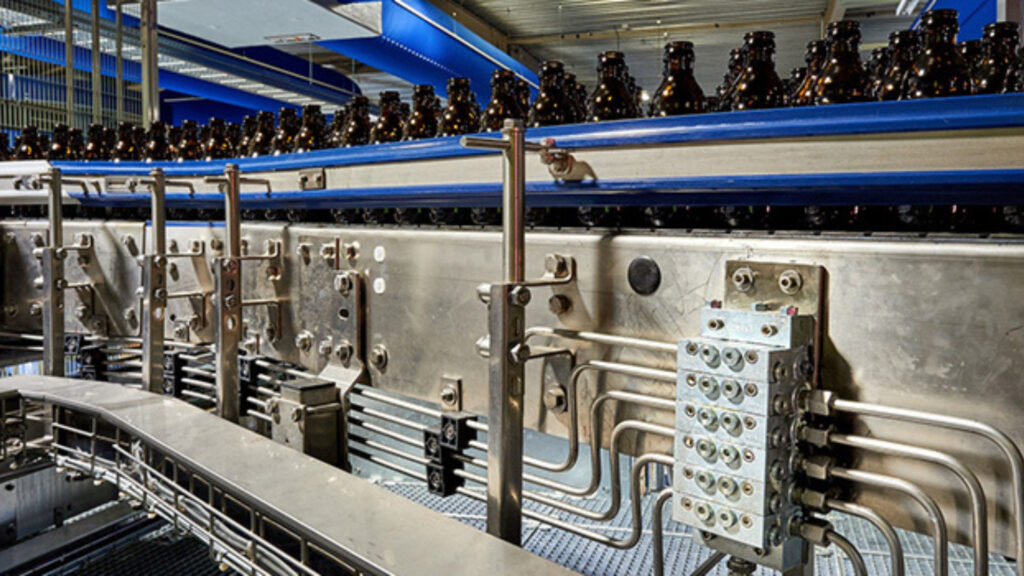

MANUFACTURING

MANUFACTURING INDUSTRY

Automatic lubrication systems on stationary equipment consistently dispense lubricant: increasing safety and reducing breakdowns. Greasing machinery in motion provides consistent lubricant coverage to critical bearings and other wear components.

FLEETS

FLEET MANAGEMENT

By utilizing Consistent Flow Lubrication for heavy duty trucks, our customers achieve:

Increased tire life and miles per gallon

Minimized component wear

Optimized labor resources

Reduced Downtime

Applications:

- Box Truck

- Cement Truck

- Coach & School Buses

- Fire Truck

- Flatbed Truck

- Refrigerator Truck

- Snow Plows

- Street Sweeper

- Tank Truck

- Tractor Trailers

- Trailers

- Waste Haulers

VEHICLE SERVICES

VEHICLE SERVICES

Streamline your workflow and move more lubricants through your shop with quality equipment to meet the varying needs of vehicle maintenance and repair. GreasePoint offers reliable, high-quality equipment you can depend on for fuel, diesel, antifreeze, oil and grease.

ASK ABOUT REMOTE MONITORING

GreaseAlert is an exclusive Industrial Internet of Things (IIoT) remote lubrication monitoring system. It proactively communicates with equipment managers alerting them to potential problems and avoiding catastrophic failures.

Decrease Consumption of Lubrication

15% of bearing failures result from insufficient lubrication quantity. Automatic lubrication systems provide small amounts of lubricant at consistent intervals, reducing the consumption of lubricant and ensuring the right amount is applied. This does not only save on the costs of oil and grease, it also protects the environment.

Minimize Machine Downtime

Unlike manual lubrication, automatic lubrication systems do not require the equipment to be shut down in order to add more oil and grease. Lock-out and tag-out procedures can be avoided, keeping the machines running while the lubrication system adds the right amount of lubricant at the right time, drastically cutting your labor and downtime.

Improve the Environment

Automatic systems measure the exact amount of lubricant required. Waste, product contamination and housekeeping issues are substantially reduced. Improved lubrication for bearings, gears and chains translates to lower friction and lower energy consumption.

Reduce Wear: Extend Equipment Life

Providing your equipment with the right amount of lubricant reduces wear and extends equipment life. Automatic lubrication releases a thin layer of oil/grease between moving parts. Components will be protected against wear and will last longer without the direct metal-to-metal contact.

Safe & Healthy Work Environments

In manually lubricated environments, a machine technician uses a grease gun to lube machine parts. Some of the vital components are difficult to reach and require climbing onto the equipment. Avoid this safety risk by the installing an automatic lubrication system.

WHAT'S THE RETURN ON INVESTMENT (ROI) OF AN AUTOMATIC LUBRICATION SYSTEM?

An investment in an automatic lubrication system for a typical piece of yellow iron, such as the Caterpillar 320 excavator, has an estimated ROI of as little as nine months. – ©Graco

- 888-631-7638

- hello@greasepoint.com

- Serving the Mid-Atlantic Region

INDUSTRIES SERVED

OUR COMPANY

OUR PROMISE TO YOU

- Technical Excellence

- High-Quality Products

- Superior Customer Service